Process

Brochure printing requires a lot of quality due to the presentation of advertisements. The use of modern printing equipment stabilizes and better colours in the brochure. In the following, we will explain each of the steps of printing a brochure, which includes the following:

- Talk to Jungle Printing and Printing Consultants

- Brochure design process

- Product lithography

- Brochure printing

- Add print features

- The process of folding or binding

- Talk to print and design consultants

Brochure printing requires careful design and proper use of equipment. Forest collection design consultants know the elements needed in a good design and use them to produce a quality brochure. Forest printing consultants also help you to produce a quality brochure at a reasonable price by choosing the type of paper and different coatings used in the product. You can provide the information in your brochure to our consultants so that they can be by your side during the production process.

Brochure design process

Once you have talked to the forest collection consultants about the information in your brochure, they will start designing the product based on this information. In this process, the size, location to be specified in the brochure, colours and many other items are specified.

Brochure lithography

Lithography is the process of converting a printed file into aluminium plates (plates) that are placed in a printing machine. Once your brochure file is ready, one-page lithography is done for them and they are ready for large-scale printing.

At this stage, the cut or size of your product is determined by the plates created in the lithography. There is no standard size for brochure printing, and the size of these aluminium plates changes according to the design and format of your custom brochure.

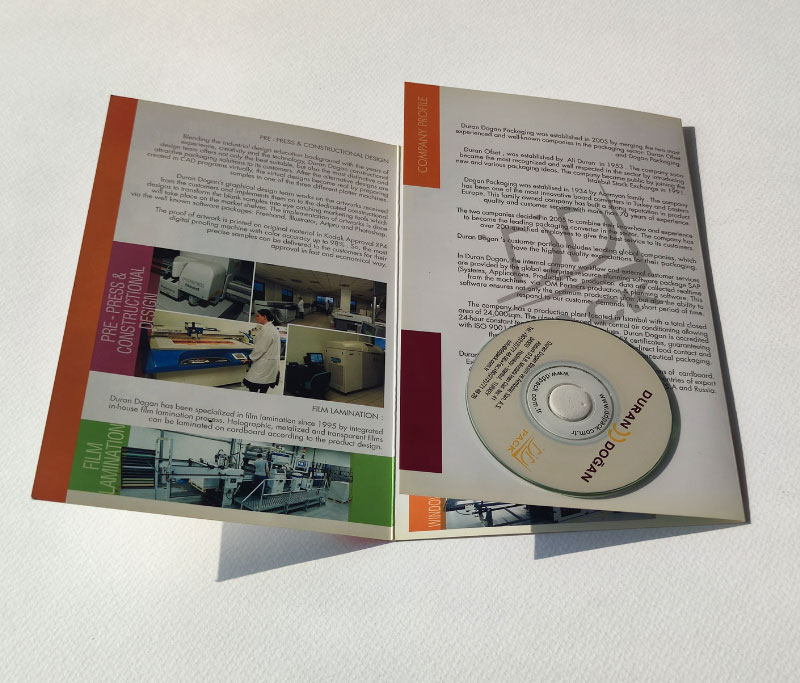

Photos of different pieces of the brochure

Production and printing

In this section, experienced forest printing staff will produce your custom product with the highest quality. Simultaneously with the production of the brochure in the printing house, the quality of the product is checked by the experts of the forest collection and the next steps are prepared.

The paper used in the brochure and the special colour stabilization coatings will be added to your brochure at this stage. Brochure printing is typically done on glossy paper because it contains colour photographs and is low due to the folding heat of these papers. (Link to the post on paper types) Forest collection printing consultants will help you choose the right paper heat for brochure printing.

Add print features

The beauty of the product makes the reader attracted at first glance to the promotional products that introduce you and your business. Powerful jungle printing equipment and experienced staff are able to create a variety of printing features to print your brochure, some of which include the following.

- Impact

- Topical UV

- Multilayer percussion

- Highlighting

Using these features will make your brochure look beautiful. Links to all types of printed features

Line up in the brochure

Once the brochures have been printed and the print features have been added, it is time to add the fold line.

Brochures, unlike many printed products, do not require binding, and since the product consists of a page that folds normally, it only needs to create a fold line. The forest collection uses the most modern printing equipment to do this for you to provide you with a smooth and functional line.

How to order

You can use the order registration form to view all the print features provided by Jungle Collection, select your desired options and order your desired product. If you have questions about the ordering or payment process, you can get help from the Frequently Asked Questions page. The Jungle Collection Consulting Team is ready to answer your questions and you can contact them in a variety of ways.

User Comments

Ask us anything